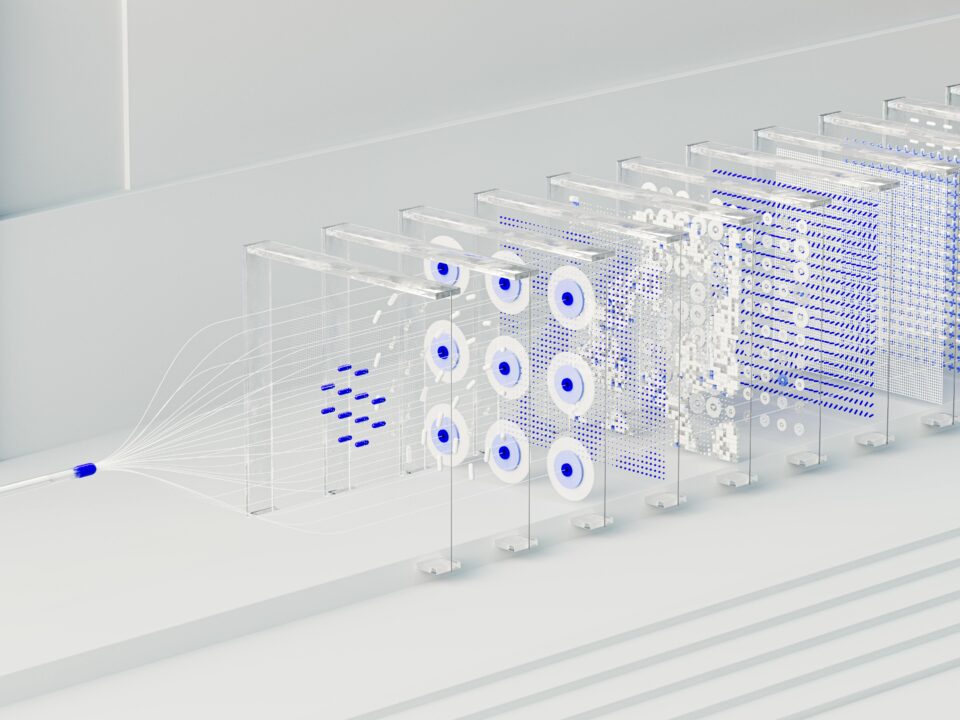

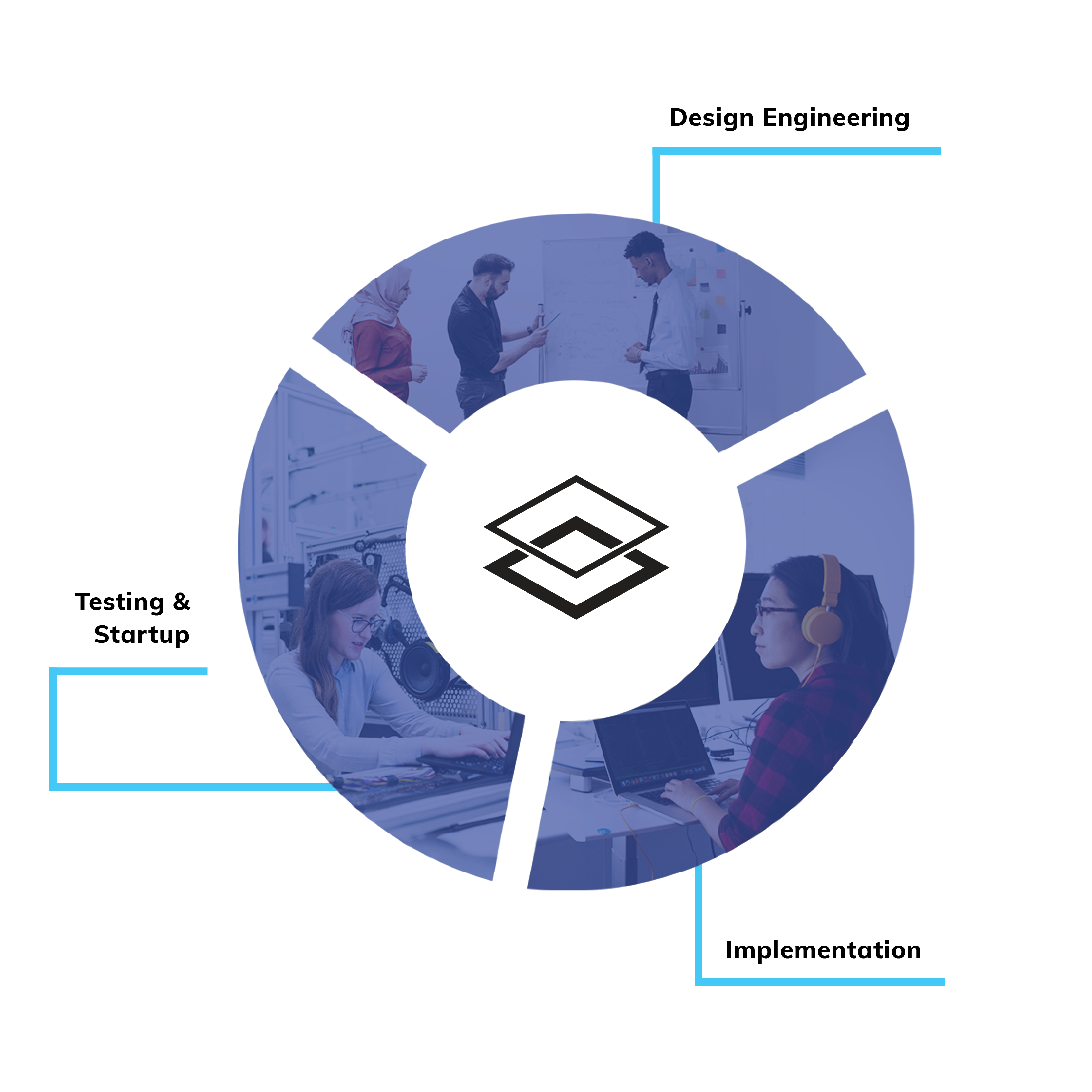

"Process Automation is a core strength of GrayMatter. We can go into any chemical, life sciences or water/wastewater facility, figure out the processes and document them, develop P&IDs, Functional Description Specification (FDS) and control strategies to come up with an appropriate solution to meet or exceed client requirements."

Design Engineering

Implementation

Testing & Startup

Design Engineering

Identify the time, materials and personnel needed to complete a project. Develop full schematics commissioning documents, checklists for equipment and controls and communication plan with key stakeholders.

- PLC Mapping & Programming

- Control Panel Modernization

- Alarm Structure Optimization

- Develop C&I system architecture, hardware, software, and applications

- Develop P&IDs

- Design Process Control Logic

- Develop detailed specifications and drawings

- Develop procedures for Maintenance of Plant Operations (MOPO) during construction

- SCADA Design/Master Planning

- HMI Screens - ISA 101

- Radio Telemetry Design

CONTROL PANEL DESIGN

- Control Panel Design (custom built from UL-listed industrial control panel shop in the U.S. and Canada)

- Control Panel Build

– UL, cUL - Control Panel QCC

– Point-to-point (conductivity)

– Power Up (test for DOA components) - Program Download

–Setup & Test communications - Factory Acceptance Test (FAT) with GrayMatter or Customer Personnel

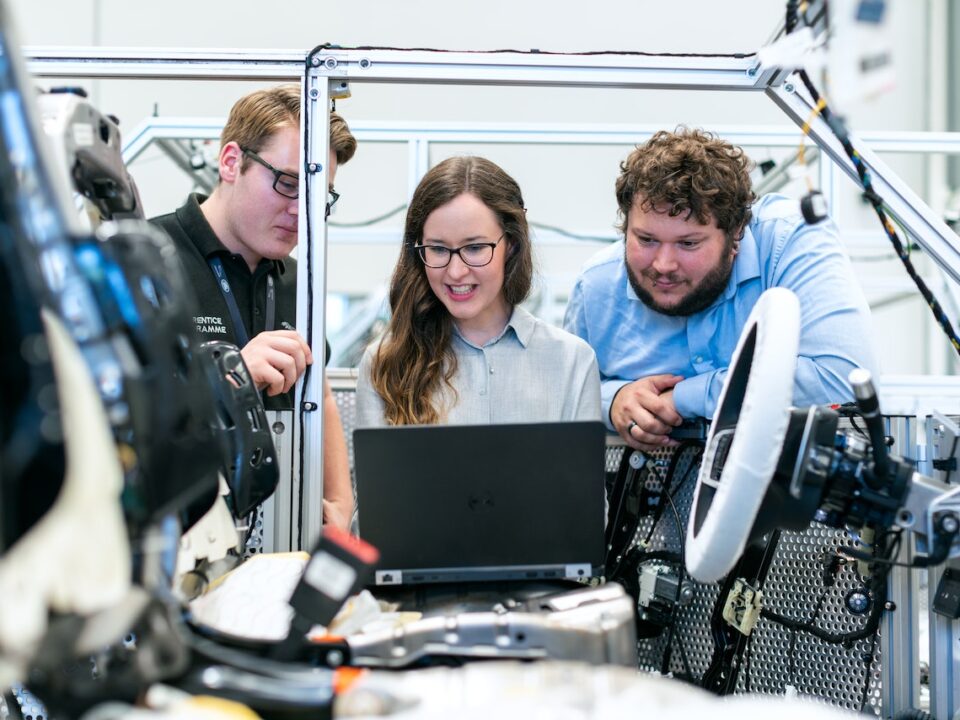

Implementation

Translate initial planning into action. Ensure data tags flow from devices to control systems and reporting and visualization tools for plant-floor operators and project leaders.

- SCADA/HMI/MES systems

– Product Agnostic Approach

– System Integration (PLCs, MES, DCS, ERP)

– Remote Monitoring and Control Implementation

– Legacy System Migration

– ANSI/ISA-Compliant Dashboards

– ISA101 Standard Application

– Customized HMI & Style Guide Development

– Alarm & Notification Management - Process and Batching Automation

– Unique PhantomTrac Solution to meet all Process Batching requirements - Machine Control

– Full-scale electrical design and automation of Material Handling Systems

– Electrical design and automation of high-precision cutting systems

– Experienced in all levels of automation in machine environments, including full development, enhancements, and remediation of existing systems - DCS/PLC-based distributed process controls

- Field devices, sensors, and instrumentation

- Industrial networking to connect shop floor PLCs with SCADA workstations

- Bridging process networks with business networks

- Telemetry over radio, leased lines, CDMA/GSM, and POTs

- Motion Applications

– Vast experience in Motion applications from simple, single axis servo systems, to multi-axis multi-machine systems - Reporting

- Validation

- Serialization

Testing & Startup

Calibrate in a passive, controlled environment and finalize go-live plans with operations and quality assurance personnel.

- Rigorous UL-listed standards, acceptance testing, panel shop, on-site control engineers

- Factory tests, calibrations, and loop checkout

- DCS/PLC programming/configuration testing

- Develop procedures for system startup

- Troubleshoot Control Logic

- Fine tune C&I loops

- Interface with plant operations, system availability and acceptance testing

ABB

Auvesy-MDT

AVEVA

AWS

CISA

Cisco

Cognex PSI

CSIA

Dell PartnerDirect

Ethical Hacker

Fortinet

GE Vernova Trainer

GE Vernova SI

Honeywell

Ignition

Microsoft

Mitsubishi Electric

OEE Downtime

PlantPAx

Rajant KMP

Rockwell Automation

Schneider Electric

Siemens

Splunk

Stratus

Systech

Tenable

ThinManager

TwinThread

VMWare

VTScada

Industries

Food & Beverage

From soft drinks and fruit juices to infant formulas, cereals and candy, GrayMatter has the requisite controls knowledge and experience in the manufacturing and packaging of food and beverage products.

-

Packaging lines

-

Process control

-

Batching control systems

-

HVAC controls

-

Process manufacturing

Life Sciences

GrayMatter provides automation solutions to some of the world’s largest life sciences companies – We have knowledge in the automation and validation of pharmaceutical process and packaging line control systems and a thorough understanding of regulatory compliance requirements.

Diversified Materials

GrayMatter helps manufacturing companies maximize throughput, lower operational costs and minimize the cost of re-engineering to accommodate changes as their facilities grow.

-

Controls design

-

PLC, DCS, and HMI application development

-

Industrial IT network design & deployment

-

Data acquisition, reporting and presentation

Process

GrayMatter provides automation and project support services for process manufacturers. We have extensive experience in the control of chemical manufacturing processes and equipment using robust DCS and PLC control technologies and associated operator interfaces.

-

Pressure, temperature & flow control

-

Batching & Continuous control systems

-

Fired equipment

-

Reactor control

-

SIL - Safety Instrumented Systems

-

Process manufacturing

-

Utilities, Water systems

Critical Infrastructure

GrayMatter has deep industry knowledge and experience working with the critical infrastructure and utility sectors.

- Evaluating/documenting of complex processes: identifying customer requirements

- SCADA/HMI/MES systems

- DCS/PLC-based distributed process controls

- Field devices, sensors, and instrumentation

- Telemetry over radio, leased lines, CDMA/GSM, and POTs

Start a Project

Ready to start a new automation and controls project? Let's talk.