Reimagine processes, create new business models & unlock value with Digital Transformation.

You’re probably already collecting the data you need from sensors on industrial equipment - There’s no shortage of raw data.

GrayMatter’s Advanced Industrial Analytics solutions build a custom-fit strategy for clients that can start from zero to jumpstart an analytics pilot in days, or incorporate the work you’ve done and help build the model that scales across your entire enterprise.

Advanced Industrial Analytics

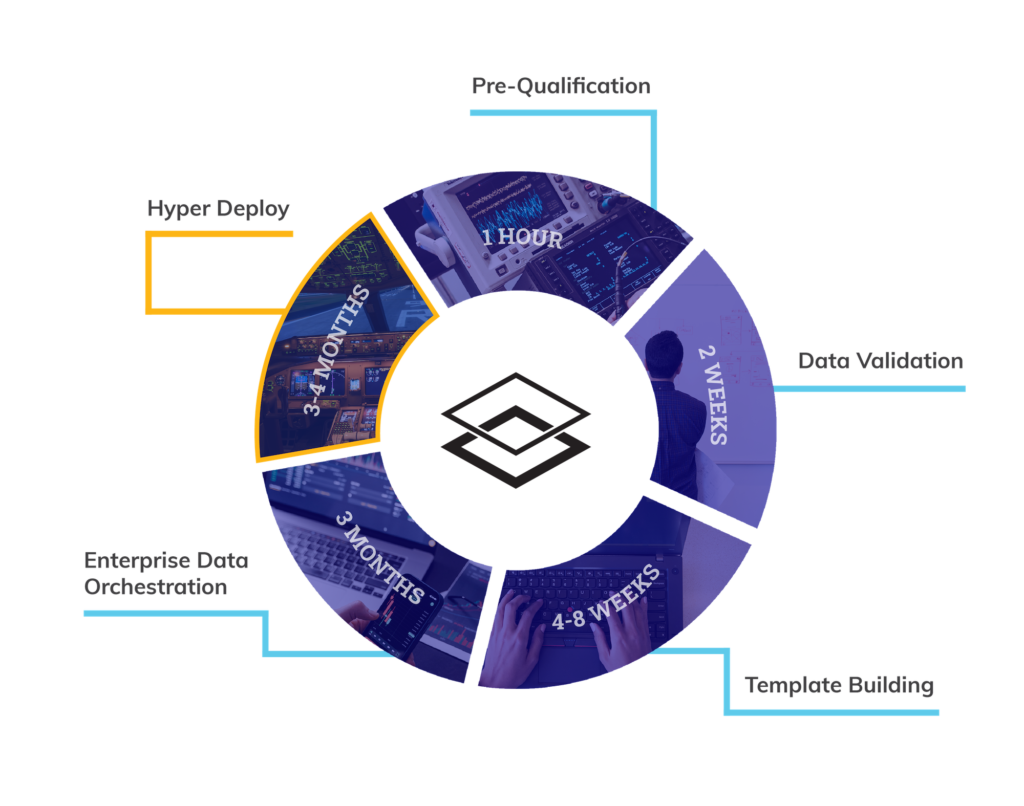

The GrayMatter Pre-Qualification Briefing is a one-hour discussion that takes your

key stakeholders through an inventory of the data you have or have not collected.

- Determine analytics strategy phase

- Discuss sample use cases and identify best fit

- Identify business potential & three business problems to solve

GrayMatter’s advanced analytics platform begins analyzing data within minutes

and making predictions within hours. We work with you to validate those predictions

and fine-tune the variables being measured over a roughly two-week process.

- Historical data ingestion & data audit

- Select and apply appropriate data analysis models

- Test initial predictions against actual results within 2 weeks

You have the data, predictions are flowing and now it’s time to scale. Within 4-8 weeks, you lead the way on building a concept for a pilot project, and GrayMatter provides guidance to help apply your concept to other facilities and operationalize predictions. That means using predictions to alert operators to make changes before a problem occurs.

- Configure a digital twin for each asset

- Automate data preparation

- Enable multi-site, real-time data comparisons

Deploying an advanced analytics strategy shouldn’t be a one-time event. The goal at this stage is to help companies use advanced analytics to automate the process of Kaizen, Lean Six Sigma or similar methodologies. The ability to use data to make predictions with data accelerates

and integrates with a company’s existing continuous improvement and enterprise analytics strategies. Some companies at this level may even want to monetize their data analytics platform for companies that purchase their services.

- Connect operational data with enterprise analytics platform & accelerate continuous improvement

- Build a customer-facing analytics service

- Develop additional use cases to scale 3 months and beyond

Advanced Industrial Analytics super-charge the expertise that’s already in the boardroom, or in the warehouse or at the well pad.

It can answer a question no one thought to ask, or offer an early alert about a pressure reading that could become a ruptured tank.

It’s about finding warning signs, plotting trends and using a virtual space to dig into real-world problems. Simply, we bring the data together, so you can take it apart.

"We help you mine your industrial data sources so you can see a 10x ROI within weeks, not months."

-CARSON DRAKE

GRAYMATTER VP